Clay-Coated Paperboard Packaging Market Emerging Trends and Demand 2032

Introduction

The Clay-Coated Paperboard Packaging Market refers to packaging materials in which paperboard substrates are coated with clay (kaolin or similar minerals) on one or more surfaces to achieve a smooth, printable, and barrier-capable finish. Such coatings enhance printability, gloss, barrier performance (light, moisture, grease), and consumer appeal, making clay-coated paperboard widely used for folding boxes, trays, sleeves, cartons, and graphic packaging.

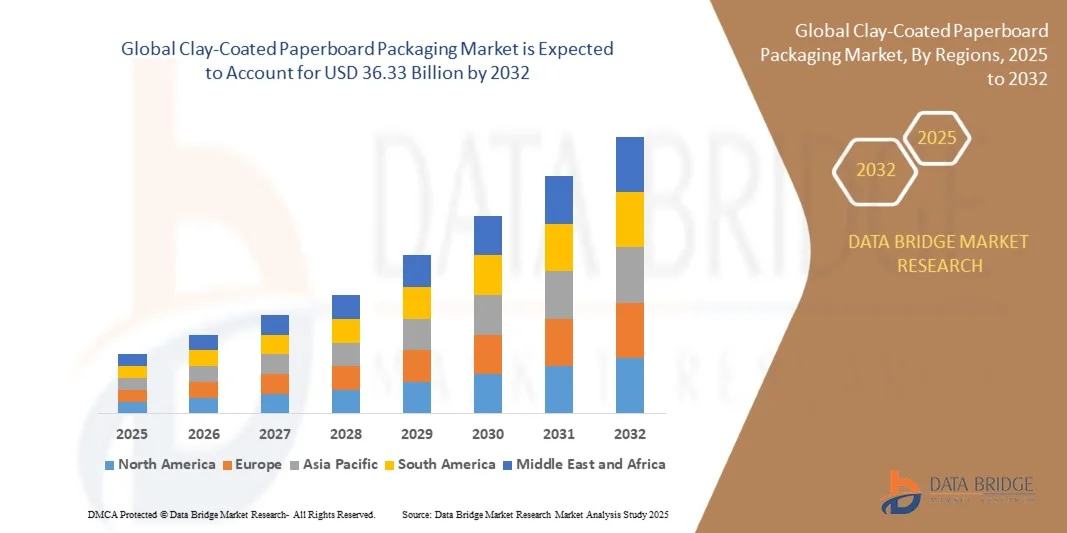

This market is important globally because brands are shifting away from plastic and toward fiber-based packaging that offers both functional performance and sustainability. Clay-coated paperboard enables high-quality visual presentation and barrier enhancements while maintaining recyclability under many systems. The packaging sector—food & beverage, personal care, pharmaceuticals, consumer goods—relies heavily on these materials. In 2024, the global clay-coated paperboard packaging market is estimated at USD 24.78 billion and is expected to grow to USD 36.33 billion by 2032, at a CAGR of 4.9% during 2025–2032. Data Bridge Market Research

Learn how the Clay-Coated Paperboard Packaging Market is evolving—insights, trends, and opportunities await. Download report: https://www.databridgemarketresearch.com/reports/global-clay-coated-paperboard-packaging-market

The Evolution

The clay-coated paperboard market has evolved in line with demand for higher aesthetic quality and functional barriers in fiber packaging.

-

Originally, paperboard packaging was uncoated or lightly treated, focusing on strength rather than surface quality.

-

In the mid-20th century, coated boards (e.g. clay coatings) began to be applied to enhance print sharpness and surface smoothness for graphical packaging.

-

The shift toward hygiene, barrier protection (moisture, grease, oils), and extended shelf life drove multilayer coatings and hybrid barrier systems.

-

Advances in coating technology—improved kaolin dispersion, pigment formulations, coating chemistries, and surface treatment—raised functional performance.

-

More recently, regulatory pressure on single-use plastics, consumer demand for sustainable packaging, and improvements in recycling infrastructure have accelerated adoption of clay-coated paperboard over plastic alternatives.

-

Development of PFAS-free barrier coatings, bio-based barriers, and improved repulpability represent innovations shaping the future.

Demand shifts have moved the market from primarily decorative packaging to performance packaging—supporting barrier and protection functionalities while still offering recyclability.

Market Trends

Several trends are driving the clay-coated paperboard packaging market:

-

Sustainability and plastic substitution: Brands are replacing plastic laminates, PVDC coatings, and multilayer barriers with fiber-based, clay-coated solutions to meet regulatory and consumer expectations of recyclability.

-

Regulation and material mandates: Restrictions on single-use plastics and mandates for recyclability are pushing brand owners toward fiber and clay-coated board.

-

Barrier innovations: Development of water-, grease-, and oxygen-resistant coatings that remain compatible with recycling systems is a key competitive differentiator.

-

High-quality graphics & premium packaging: Clay-coated surfaces support high-resolution printing, special effects (spot UV, embossing), and premium branding.

-

E-commerce and shelf-ready packaging: Demand for well-presented, protective, branded boxes suited for direct shipment supports growth in clay-coated paperboard.

-

Supply chain resiliency and localization: Regional capacity expansion of mills and coating lines helps reduce dependence on imports and logistics risk.

-

Focus on repulpability & recyclability: Coating systems that avoid interfering with recycling (e.g., ease of deinking) become more valuable.

-

Digitalization & customization: Short-run digital printing on clay-coated substrates enhances flexibility and lowers inventory requirements.

In regional patterns, Asia-Pacific currently dominates consumption and capacity. North America and Europe are focusing heavily on regulatory compliance, sustainability, and performance differentiation.

Challenges

The market faces multiple challenges:

-

Cost of raw materials and coating inputs: Kaolin, pigments, binders, and specialty additives are subject to supply volatility.

-

Technical complexity in coating: Achieving consistent, defect-free coatings across large board surfaces is demanding.

-

Recycling compatibility: Some coatings or barrier layers impair repulpability or deinking processes, reducing recyclability.

-

Barrier performance limitations: Fiber-based systems still struggle to match high-barrier plastics in some applications (e.g., deep freeze, high moisture).

-

Capital investment and retrofit costs: Upgrading mills or adding coating capacity is capital-intensive and time-consuming.

-

Regulatory shifts and evolving sustainability standards: Changing environmental regulations (e.g., PFAS bans, compostability, recyclability mandates) push constant adaptation.

-

Competition from flexible packaging and alternative substrates: In many packaging categories, flexible films or plastics still hold cost or barrier advantages.

-

Supply chain disruptions: Logistics, energy costs, and raw material constraints can impact operations and margins.

Risks include sudden regulatory change, supply chain shocks, technology disruption (e.g. new barrier films), and shifts in consumer or brand behavior.

Market Scope

Segmentation by Board Grade / Coated Type

-

Solid Bleached Sulfate (SBS) with clay coating

-

Coated Unbleached Kraft Board

-

Coated Recycled Board (CRB) with clay coating

-

Clay-Coated Newsback

-

White-Top Kraftliner

-

Single clay-coated versus double clay-coated surfaces

Segmentation by End-Use / Application

-

Food & Beverage (e.g. cereal boxes, trays, frozen food cartons)

-

Consumer Goods & Personal Care

-

Healthcare & Pharmaceuticals

-

Industrial & Chemicals

-

Others (electronics packaging, gift boxes, etc.)

Segmentation by Barrier / Coating Technology

-

Clay-only coatings

-

Clay + barrier additive coatings

-

Multi-coat / composite barrier (clay + polymer / hybrid)

Regional Segmentation

-

North America

-

Europe

-

Asia-Pacific

-

Latin America

-

Middle East & Africa

End-User Industries

-

Food & Beverage Manufacturers

-

Consumer Goods / FMCG Brands

-

Cosmetics / Personal Care

-

Pharmaceutical Companies

-

Industrial / Chemical Companies

-

E-commerce & Retail Brands

Regional Analysis & Adoption Patterns

-

Asia-Pacific leads with ~41.7% share in 2024, driven by strong consumption in packaging, rapid industrialization, and expanded capacity in China, India, and Southeast Asia. Data Bridge Market Research+1

-

Europe and North America focus on premium packaging and sustainability, with steady growth. Strict regulations and consumer demand push brand owners toward recyclable clay-coated board.

-

Latin America and Middle East & Africa are gradually increasing adoption, especially in packaging of food, beverages, and consumer goods, though infrastructure and recycling systems limit uptake.

-

E-commerce growth in many regions accelerates demand for shelf-ready and branded outer packaging that is visually attractive and protective.

Market Size and Factors Driving Growth

Current Valuation & Forecast

The global clay-coated paperboard packaging market size was valued at USD 24.78 billion in 2024 and is expected to reach USD 36.33 billion by 2032, at a CAGR of 4.9% during the forecast period

Major Drivers

-

Plastic-to-fiber substitution: As brands move away from plastic packaging, clay-coated board offers a fiber alternative with decent performance.

-

Regulatory and sustainability pressure: Laws banning or limiting single-use plastics and requiring recyclable packaging increase demand.

-

Growth in packaged food, beverages, cosmetics, and e-commerce: Rising consumption and online retail drive demand for visually appealing, functional packaging.

-

Advances in barrier coatings and additive technologies: Improving barrier performance without hindering recyclability enables deeper penetration into challenging segments.

-

Brand differentiation via high-quality graphics: Clay-coated surfaces support high-fidelity printing and premium finishes.

-

Mill capacity expansion and modernization: New coating lines and improvements in existing mill infrastructure increase supply and performance.

-

Consumer preference for sustainable packaging: Brand loyalty increasingly tied to environmental credentials.

Opportunities in Emerging Regions

-

Large growth potential in India, Southeast Asia, Latin America, and Africa as consumption, packaged goods, and recycling infrastructure improve.

-

Upgrading recycling and pulp infrastructure in emerging markets to support clay-coated material recovery.

-

Local mill investments and regional coating capacity reduce import dependency and logistic costs.

-

Innovation in low-cost barrier coatings and deinkable clay systems suited for local recycling systems.

Conclusion

The Clay-Coated Paperboard Packaging Market is positioned for sustained growth. With a base of approximately USD 24.78 billion in 2024 and projected to reach USD 36.33 billion by 2032 at ~4.9% CAGR, the market is likely to continue expanding beyond 2032 into the USD 40–45 billion+ range by 2035, assuming continued substitution, innovation, and geographic reach. Data Bridge Market Research

Success in this market depends on balancing performance, cost, and recyclability. Innovations in barrier coatings, deinkability, and coating technologies will be critical. Regional capacity development, localized supply chains, and alignment with sustainability mandates will determine competitive positioning. Brand demand for premium visual packaging and regulatory shifts away from plastic provide tailwinds.

For stakeholders—millers, coating technology providers, converters, brand owners—the path forward lies in investing in flexible coating lines, barrier technology R&D, sustainability in recycling, and regional footprint expansion.

Frequently Asked Questions (FAQ)

Q1: What is the current value of the clay-coated paperboard packaging market?

A1: In 2024, it is estimated at USD 24.78 billion globally. Data Bridge Market Research

Q2: What CAGR is projected through 2032?

A2: About 4.9% per year from 2025 to 2032. Data Bridge Market Research

Q3: Which region leads the market?

A3: Asia-Pacific, accounting for ~41.7% of market share in 2024. Data Bridge Market Research

Q4: What are common board grades in this market?

A4: Solid bleached sulfate, coated unbleached kraft, coated recycled board, white-top kraftliner, clay-coated newsback, etc. Data Bridge Market Research

Q5: Which end-use industry is the largest user?

A5: Food & beverage packaging, followed by consumer goods, personal care, and healthcare. Data Bridge Market Research+1

Q6: What major trend is influencing market growth?

A6: Substitution of plastics with fiber packaging driven by sustainability demands, regulatory pressure, and innovations in barrier coatings.

Browse More Reports:

North America Plant-Based Egg Market

Middle East and Africa Plant-Based Egg Market

Latin America Plant Breeding and CRISPR Plant Market

Europe Plant Breeding and CRISPR Plant Market

Asia-Pacific Plant Breeding and CRISPR Plant Market

Middle East and Africa Plant Breeding and CRISPR Plant Market

North America Plant Breeding and CRISPR Plant Market

North America and Latin America Plant Breeding and CRISPR Plants Market

Asia-Pacific Respiratory Diagnostics Market

North America Respiratory Diagnostics Market

Europe Respiratory Diagnostics Market

Middle East and Africa Respiratory Diagnostics Market

Europe Revenue Cycle Management Market

Asia-Pacific Revenue Cycle Management Market

Europe RFID (Radio Frequency Identification) Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness